Chapter 4: Waves of Technology

Pennsylvania's century-long mantle as "steel making capital of the world" pivoted on four successive waves of steelmaking technologies. While the iron industry that developed in colonial Pennsylvania featured modest-scale mills, such as the  Alliance Furnace which depended on highly skilled workers, the high-volume steel industry developing in the 1870s relied more on complex machines than skilled workers.

Alliance Furnace which depended on highly skilled workers, the high-volume steel industry developing in the 1870s relied more on complex machines than skilled workers.

The famed Pennsylvania steel industry was born in the fiery blast of the Bessemer converter. Next, open-hearth furnaces made higher quality steel for skyscrapers, bridges, and ships, while alloy steels from crucible and electric furnaces led to the entire modern steel-based society.

Then, around 1900, nervous investment bankers were spurred to consolidate a complex of industries including steel making, ship and rail transport, and new finishing plants.For decades this consolidated industry, with U.S. Steel first and foremost US Steel generated prosperity for stockholders and steelworkers.

US Steel generated prosperity for stockholders and steelworkers.

Unfortunately, a fourth wave of technology took the industry by surprise. American efforts to catch up with foreign steelmakers that switched over to basic oxygen furnaces and continuous casting in the 1950s and 1960s did not come swiftly enough. This led to the tragic collapse of the U.S. steel industry in the 1980s, when fully half of all steel jobs vanished.

Before the 1870s, skilled workers such as James Davis dominated the iron industry. Born in Wales, and fiercely proud of his kin and culture, Davis took immense satisfaction in having made "master puddler" by age sixteen. In The Iron Puddler, his singular first-hand account of ironmaking, Davis vividly described the arm-busting work of "puddling the metal in its glaring bath," coaxing the iron to "come to nature," and forming it into 200 pound masses for the mechanical squeezer to work on.

"come to nature," and forming it into 200 pound masses for the mechanical squeezer to work on.

Davis arrived in Pennsylvania in the 1880s when the changeover from iron to steel was in full swing. He traveled endlessly "to chase the fireflies of vanishing jobs" after the iron mills where he apprenticed in Sharon, Pennsylvania, closed down.

Unfortunately, he found iron mills were also closing in Pittsburgh, where "a man with hungry children would be given a furnace for a few days to earn enough to ward off starvation," and elsewhere. Finally, he found work in Elwood, Indiana. We know his story today because Davis climbed through the ranks of unions and municipal government to become U.S. Secretary of Labor in the 1920s. His battling through tough times provides a counterpoint to the saga of success personified by

Pittsburgh, where "a man with hungry children would be given a furnace for a few days to earn enough to ward off starvation," and elsewhere. Finally, he found work in Elwood, Indiana. We know his story today because Davis climbed through the ranks of unions and municipal government to become U.S. Secretary of Labor in the 1920s. His battling through tough times provides a counterpoint to the saga of success personified by  Andrew Carnegie.

Andrew Carnegie.

Carnegie's genius was to transform the first two waves of steelmaking technology - Bessemer converters and open-hearth furnaces - into a machine for making money. "A perfect mill is the road to wealth," he once bragged. While preaching, "pioneering don't pay," he followed quite different advice. Quickly deploying new steelmaking technologies, and relentlessly driving his managers and workers, Carnegie created an empire in steel where pioneering paid very well indeed. It began with railroads.

Carnegie created an empire in steel where pioneering paid very well indeed. It began with railroads.

"The country was building, and I gave it iron to build with," wrote Davis gallantly. "Railroads were still pushing out their mighty arms and stringing their iron rails across the western wheat lands. American railroads initially depended on iron rails rolled in a "three-high" rail mill invented in the 1850s by John Fritz at Cambria Iron.

John Fritz at Cambria Iron.

Rail mills built to Fritz's design were soon rolling as much metal as iron puddlers could provide. Railroads clamored for even more. They sparingly used steel rails imported from Britain since these cost $160 per ton, twice the cost of iron rails. Cambria pioneered in making steel and

making steel and  rolling steel rails.

rolling steel rails.

Cambria also hosted Alexander Holley, the widely traveled engineer who designed the country's first dozen Bessemer steel mills. In mastering the Bessemer process, Holley traveled to Britain so often that some accounts mistakenly describe him as English (he grew up in Connecticut). The railroads that strung rails across the "western wheat lands" did so not with Davis' iron but with steel from Holley's mills.

Andrew Carnegie began his conquest of the Pennsylvania - and American - steel industry in 1875 when he opened the "Edgar Thomson" mill (ET), named for the president of the Pennsylvania Railroad. Carnegie had tried making steel rails at Freedom Iron, but his ET works in Braddock, on the Monongahela, were designed for the task from the ground up.

Freedom Iron, but his ET works in Braddock, on the Monongahela, were designed for the task from the ground up.

Here, Holley designed a steelmaking and rail-rolling complex that Carnegie staffed by a former crew from Cambria, led by Captain William Jones. The Bessemer converters at ET and elsewhere used special machinery and a blast of air to convert molten, raw pig iron into white-hot steel. Fritz-style rolling mills then spat out steel rails. Steel rail prices tumbled to $40 per ton, while iron rails literally went on the scrap heap.

Captain William Jones. The Bessemer converters at ET and elsewhere used special machinery and a blast of air to convert molten, raw pig iron into white-hot steel. Fritz-style rolling mills then spat out steel rails. Steel rail prices tumbled to $40 per ton, while iron rails literally went on the scrap heap.

In the eyes of Holley and other steelmaking pioneers, a Bessemer blow was at once violent and beautiful. By around 1900, steel rails passed through the rolling mills along an entirely

Bessemer blow was at once violent and beautiful. By around 1900, steel rails passed through the rolling mills along an entirely  mechanized path in which "no human hand has touched it, from beginning to end." Bessemer steel mills needed engineers like

mechanized path in which "no human hand has touched it, from beginning to end." Bessemer steel mills needed engineers like  John Fritz, who continued his innovations at Bethlehem Steel, able chemists and watchful machine tenders, but not the arm-and-eye skills of iron puddlers. "Thousands of dollars are spent to dispense with the labor of one or two men," wrote one metallurgist.

John Fritz, who continued his innovations at Bethlehem Steel, able chemists and watchful machine tenders, but not the arm-and-eye skills of iron puddlers. "Thousands of dollars are spent to dispense with the labor of one or two men," wrote one metallurgist.

The coming of Bessemer steel altered the lives of the industry's workers. Since traditional iron mills could not run without them, skilled workers had substantial leverage over wages and working conditions. A number of iron trade unions, which united as the Amalgamated Association, had flourished. But the new steel mills depended instead on machinery, and required far more semiskilled operatives and unskilled laborers than skilled workers. While a skilled ironworker might need three years to learn his craft, a semiskilled operative might learn his job in three weeks.

Amalgamated Association, had flourished. But the new steel mills depended instead on machinery, and required far more semiskilled operatives and unskilled laborers than skilled workers. While a skilled ironworker might need three years to learn his craft, a semiskilled operative might learn his job in three weeks.

Time and again, the steel mills undercut the iron trade unions and took greater control of the workplace. In the mid-1880s Amalgamated president William Weihe admitted, "Every strike that has thus far taken place in our Bessemer steel mills has gone against us."

control of the workplace. In the mid-1880s Amalgamated president William Weihe admitted, "Every strike that has thus far taken place in our Bessemer steel mills has gone against us."

"Bridges were crossing the Mississippi and spanning the chasms in the Rocky Mountains. Chicago and New York were rising in new growth with iron in their bones to hold them high." Iron puddler Davis again got it half right.

While John Roebling's first factory in Saxonburg, Pennsylvania made iron cables, originally for the

John Roebling's first factory in Saxonburg, Pennsylvania made iron cables, originally for the  Allegheny Portage Railroad, his new factory in Trenton, New Jersey, cranked out steel ones. The two most famous bridges of the age - the Eads bridge over the Mississippi and the Roeblings" Brooklyn Bridge - were built with steel. Steel was used in most tall buildings in Chicago beginning in the mid-1880s and soon after also in New York. Steel bones would hold high the skyscrapers of American cities.

Allegheny Portage Railroad, his new factory in Trenton, New Jersey, cranked out steel ones. The two most famous bridges of the age - the Eads bridge over the Mississippi and the Roeblings" Brooklyn Bridge - were built with steel. Steel was used in most tall buildings in Chicago beginning in the mid-1880s and soon after also in New York. Steel bones would hold high the skyscrapers of American cities.

The Bessemer blast made low-quality steel acceptable for rails, but to manufacture the higher-quality steel needed for bridges and buildings Pennsylvania steel makers built new open-hearth furnaces. An open-hearth furnace turned the Bessemer converter on its side, figuratively and literally. While upright Bessemer converters blew air through molten iron, generating a white-hot blast that might last twenty minutes or less, open-hearth furnaces made iron into steel in a horizontal hearth that used high temperatures alone.

Time was the key. An open hearth "heat" up to twenty-four hours gave steelmakers much greater quality control. All the principal steel plants, including Bethlehem and Midvale in Philadelphia, built open-hearth furnaces, retiring their Bessemer converters and the distinctive blast that severely fouled the air.

It is surprisingly difficult to recapture work life in an open-hearth steel mill, despite the fact that many thousands of workers labored in them. Though larger than most, U.S. Steel's Duquesne Steel open-hearth mill typically employed roughly one-third each skilled workers (e.g. melters, first helpers, millwrights), semiskilled workers (crane operators, second helpers, and third helpers), and unskilled workers (common labor).

Duquesne Steel open-hearth mill typically employed roughly one-third each skilled workers (e.g. melters, first helpers, millwrights), semiskilled workers (crane operators, second helpers, and third helpers), and unskilled workers (common labor).

An unusual first-hand account is Charles Walker's Steel: A Diary of a Furnace Worker (1922). Walker narrates his entry to the Jones and Laughlin mill at Aliquippa, where at first he shoveled slag and chipped metal out of a casting pit. He later advanced onto the steelmaking floor as a semiskilled helper: "I looked up and saw the big ladle-bucket pouring hot metal into a spout in the furnace-door, accompanied by a great swirl of sparks and flame, spurting upward with a sizzle. ‘At last," I said,

out of a casting pit. He later advanced onto the steelmaking floor as a semiskilled helper: "I looked up and saw the big ladle-bucket pouring hot metal into a spout in the furnace-door, accompanied by a great swirl of sparks and flame, spurting upward with a sizzle. ‘At last," I said,  ‘I'm going to make steel." The legion of unskilled workers is even more difficult to document. A truly singular case was the pig-iron handler

‘I'm going to make steel." The legion of unskilled workers is even more difficult to document. A truly singular case was the pig-iron handler  Henry Noll.

Henry Noll.

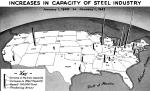

A third wave of technologies - an interlocking set of steelmaking, transport, finishing, and financing - brought about the "merger of mergers" that structured the American steel industry for the entire twentieth century.

In 1899, New York financier J. P. Morgan acquired the National Tube Works in McKeesport, triggering a great battle for control of the nation's finishing mills. Not to be outdone, Carnegie threatened to build new tube works at Duquesne - just opposite McKeesport - and at Lake Erie near the Pennsylvania-Ohio border. Also furious with Carnegie for disrupting his immense railroad enterprise, Morgan resolved to send Carnegie into retirement.

National Tube Works in McKeesport, triggering a great battle for control of the nation's finishing mills. Not to be outdone, Carnegie threatened to build new tube works at Duquesne - just opposite McKeesport - and at Lake Erie near the Pennsylvania-Ohio border. Also furious with Carnegie for disrupting his immense railroad enterprise, Morgan resolved to send Carnegie into retirement.

In January of 1901 Morgan convinced Carnegie to sell his steel empire for the sum of $480 million, creating the centerpiece of U.S. Steel, the nation's first billion-dollar corporation.

In the previous thirty years, Carnegie had become the world's largest steel manufacturer by winning control of, or "vertically integrating," each step of steel production from the mining and transport of iron ore through iron smelting and steel making. Morgan's mammoth U.S. Steel Corporation now added steel finishing to this "vertically integrated" structure. U.S. Steel owned everything needed to transform Minnesota iron ore into barbed wire or bicycle tubes.

bicycle tubes.

Morgan's strategy was to arrange "stability" for the steel industry in part by stamping out disruptive technological innovations. In its first two decades, U.S. Steel declined to develop oversize structural shapes and continuous sheet rolling.

From the 1930s through the 1960s U.S. Steel and the smaller companies in its wake generated immense profits, while the coming of steel unionism forced companies to hike wages. Such Pennsylvania firms as Dravo Corporation contributed to the military build-up of the two world wars and subsequent Cold War. But with hindsight one can see that U.S. Steel arranged too much stability and not enough innovation. Even

Dravo Corporation contributed to the military build-up of the two world wars and subsequent Cold War. But with hindsight one can see that U.S. Steel arranged too much stability and not enough innovation. Even  Bethlehem, which had a terrific record of technical innovation through the 1920s, became in the 1950s both immensely wealthy and immensely complacent.

Bethlehem, which had a terrific record of technical innovation through the 1920s, became in the 1950s both immensely wealthy and immensely complacent.

Unfortunately, a fourth wave of steel technologies in the 1950s and 1960s - basic-oxygen furnaces and continuous casting - caught the U.S. industry unawares. While Germany, Japan, and other steelmaking nations built brand-new capacity with them, the American industry bulked up on outmoded open-hearth furnaces and standard ingot casting.

In 1980, continuous casting accounted for almost 60 percent of steel output in Japan and 35 percent in Western Europe, but only 20 percent in the United States. The tragic collapse of the 1980s - when industry employment shrank from 400,000 to 200,000 jobs - centered on the shutdown of these out-of-date steel plants. It devastated many Pennsylvania mill towns.

industry employment shrank from 400,000 to 200,000 jobs - centered on the shutdown of these out-of-date steel plants. It devastated many Pennsylvania mill towns.

The famed Pennsylvania steel industry was born in the fiery blast of the Bessemer converter. Next, open-hearth furnaces made higher quality steel for skyscrapers, bridges, and ships, while alloy steels from crucible and electric furnaces led to the entire modern steel-based society.

Then, around 1900, nervous investment bankers were spurred to consolidate a complex of industries including steel making, ship and rail transport, and new finishing plants.For decades this consolidated industry, with U.S. Steel first and foremost

Unfortunately, a fourth wave of technology took the industry by surprise. American efforts to catch up with foreign steelmakers that switched over to basic oxygen furnaces and continuous casting in the 1950s and 1960s did not come swiftly enough. This led to the tragic collapse of the U.S. steel industry in the 1980s, when fully half of all steel jobs vanished.

Before the 1870s, skilled workers such as James Davis dominated the iron industry. Born in Wales, and fiercely proud of his kin and culture, Davis took immense satisfaction in having made "master puddler" by age sixteen. In The Iron Puddler, his singular first-hand account of ironmaking, Davis vividly described the arm-busting work of "puddling the metal in its glaring bath," coaxing the iron to

Davis arrived in Pennsylvania in the 1880s when the changeover from iron to steel was in full swing. He traveled endlessly "to chase the fireflies of vanishing jobs" after the iron mills where he apprenticed in Sharon, Pennsylvania, closed down.

Unfortunately, he found iron mills were also closing in

Carnegie's genius was to transform the first two waves of steelmaking technology - Bessemer converters and open-hearth furnaces - into a machine for making money. "A perfect mill is the road to wealth," he once bragged. While preaching, "pioneering don't pay," he followed quite different advice. Quickly deploying new steelmaking technologies, and relentlessly driving his managers and workers,

"The country was building, and I gave it iron to build with," wrote Davis gallantly. "Railroads were still pushing out their mighty arms and stringing their iron rails across the western wheat lands. American railroads initially depended on iron rails rolled in a "three-high" rail mill invented in the 1850s by

Rail mills built to Fritz's design were soon rolling as much metal as iron puddlers could provide. Railroads clamored for even more. They sparingly used steel rails imported from Britain since these cost $160 per ton, twice the cost of iron rails. Cambria pioneered in

Cambria also hosted Alexander Holley, the widely traveled engineer who designed the country's first dozen Bessemer steel mills. In mastering the Bessemer process, Holley traveled to Britain so often that some accounts mistakenly describe him as English (he grew up in Connecticut). The railroads that strung rails across the "western wheat lands" did so not with Davis' iron but with steel from Holley's mills.

Andrew Carnegie began his conquest of the Pennsylvania - and American - steel industry in 1875 when he opened the "Edgar Thomson" mill (ET), named for the president of the Pennsylvania Railroad. Carnegie had tried making steel rails at

Here, Holley designed a steelmaking and rail-rolling complex that Carnegie staffed by a former crew from Cambria, led by

In the eyes of Holley and other steelmaking pioneers, a

The coming of Bessemer steel altered the lives of the industry's workers. Since traditional iron mills could not run without them, skilled workers had substantial leverage over wages and working conditions. A number of iron trade unions, which united as the

Time and again, the steel mills undercut the iron trade unions and took greater

"Bridges were crossing the Mississippi and spanning the chasms in the Rocky Mountains. Chicago and New York were rising in new growth with iron in their bones to hold them high." Iron puddler Davis again got it half right.

While

The Bessemer blast made low-quality steel acceptable for rails, but to manufacture the higher-quality steel needed for bridges and buildings Pennsylvania steel makers built new open-hearth furnaces. An open-hearth furnace turned the Bessemer converter on its side, figuratively and literally. While upright Bessemer converters blew air through molten iron, generating a white-hot blast that might last twenty minutes or less, open-hearth furnaces made iron into steel in a horizontal hearth that used high temperatures alone.

Time was the key. An open hearth "heat" up to twenty-four hours gave steelmakers much greater quality control. All the principal steel plants, including Bethlehem and Midvale in Philadelphia, built open-hearth furnaces, retiring their Bessemer converters and the distinctive blast that severely fouled the air.

It is surprisingly difficult to recapture work life in an open-hearth steel mill, despite the fact that many thousands of workers labored in them. Though larger than most, U.S. Steel's

An unusual first-hand account is Charles Walker's Steel: A Diary of a Furnace Worker (1922). Walker narrates his entry to the Jones and Laughlin mill at Aliquippa, where at first he shoveled slag and chipped metal

A third wave of technologies - an interlocking set of steelmaking, transport, finishing, and financing - brought about the "merger of mergers" that structured the American steel industry for the entire twentieth century.

In 1899, New York financier J. P. Morgan acquired the

In January of 1901 Morgan convinced Carnegie to sell his steel empire for the sum of $480 million, creating the centerpiece of U.S. Steel, the nation's first billion-dollar corporation.

In the previous thirty years, Carnegie had become the world's largest steel manufacturer by winning control of, or "vertically integrating," each step of steel production from the mining and transport of iron ore through iron smelting and steel making. Morgan's mammoth U.S. Steel Corporation now added steel finishing to this "vertically integrated" structure. U.S. Steel owned everything needed to transform Minnesota iron ore into barbed wire or

Morgan's strategy was to arrange "stability" for the steel industry in part by stamping out disruptive technological innovations. In its first two decades, U.S. Steel declined to develop oversize structural shapes and continuous sheet rolling.

From the 1930s through the 1960s U.S. Steel and the smaller companies in its wake generated immense profits, while the coming of steel unionism forced companies to hike wages. Such Pennsylvania firms as

Unfortunately, a fourth wave of steel technologies in the 1950s and 1960s - basic-oxygen furnaces and continuous casting - caught the U.S. industry unawares. While Germany, Japan, and other steelmaking nations built brand-new capacity with them, the American industry bulked up on outmoded open-hearth furnaces and standard ingot casting.

In 1980, continuous casting accounted for almost 60 percent of steel output in Japan and 35 percent in Western Europe, but only 20 percent in the United States. The tragic collapse of the 1980s - when