Image

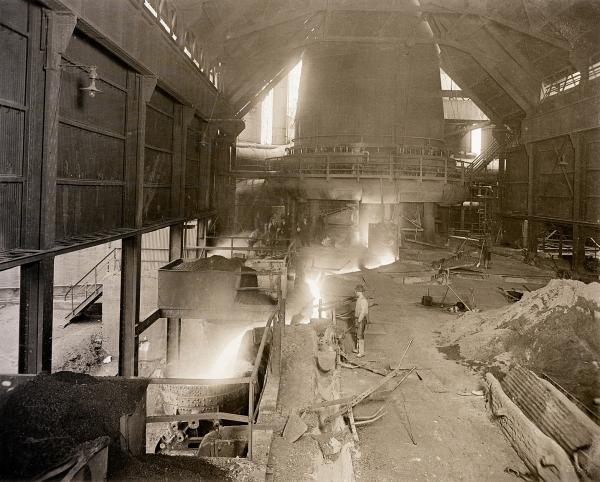

Tapping a hit blast furnace at the Carnegie-Illinois Steel Corp., Duquesne, PA, circa 1936.

Credit: Image Donated by Corbis-Bettmann

Tapping a blast furnace was the first step in making steel. Removing a clay cap from the bottom of a super heated blast furnace allowed the liquid steel to channel through a runner, usually lined with clay or fire brick, into an immense ladle or a fire brick lined rail car. Slag and impurities were skimmed off the surface of the molten steel as it moved through the runner. Blast furnaces could be tapped as often as five times a day when the mills were working at full capacity.